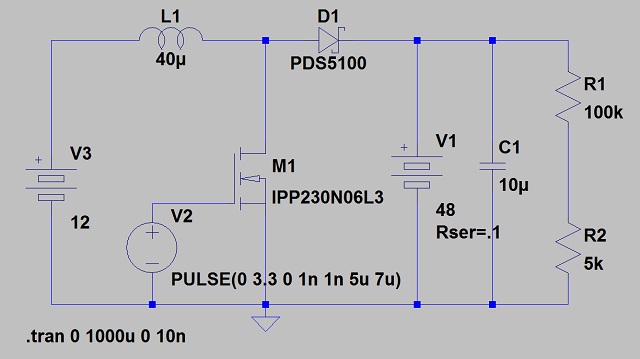

I am in the process of designing a 48 VDC (comprised of 4 x 12 VDC) lead-acid battery charger, with an input voltage of 12 VDC. 1W - 2W output is sufficient, and relatively high efficiency with low quiescent current are important. I have looked at many of battery charger ICs and none that I have found can handle 48V output. The image link below (sorry, my reputation is not high enough to post images) is a first pass at custom charger. The pulse supply (V2) would be replaced with a small, low-power microcontroller that samples the voltage at the divider. It could also have a thermistor to adjust the charging target voltage for temperature.

Based on my design criteria does this seem like a reasonable approach? Perhaps there is a charger IC I missed, or maybe a commercial off the shelf charger I do not know about?

Any suggestions, including parts to consider or modifications to my boost converter would be greatly appreciated.

FETs - Single IPP230N06L3G datasheet:http://www.kynix.com/uploadfiles/pdf9675/IPP230N06L3G.pdf

Diodes, Rectifiers - Single PDS5100-13 datasheet:http://www.kynix.com/uploadfiles/pdf65976/PDS5100-13.pdf

Simple boost-style 48V battery charger

Added:

Not sure if this is the correct way to add additional content.

450 W*hr is correct. The internal battery pack is 28 D cell alkaline batteries in series. We wish to use this internal battery back as an "emergency" backup battery. This is useful if we get frayed wires, blown fuses, charger failures or a long streak of cloudy weather. The internal pack and external supply (what I am designing) are diode protected so in any of the above "emergency" cases if our external supply drops below a certain voltage the internal pack will take over and merrily supply the ADCP for another 6-8 months. This is the main reason for selecting 48V for our supply. Yes, we may be capable of modifying the internal pack... but getting permission is another story.

While I fully support the use of LiFePO4 (As an Engineer I think they rock in so many ways), SLA has proven very robust in the harsh marine environment and no one in the group other than myself and possibly one other are interested in trying a new battery technology. Mostly the idea of spending $6k/day to replace a failed battery scares them.

Initially I designed a dual-phase 12V - 48V step up converter (kicad schematic and pcb files) and quickly discovered that this is perhaps infuriating instrument in existence. Shortly before the ADCP collects its ensemble it basically shorts the power pins (it draws > 3A @ 48V for < 10 us). I know it has to boost the voltage to several thousand volts for the transducer so I can only imagine that the ADCP opened a relay to its SMPS. This transient current draw which is is more than 11 A from the main battery causes a large voltage spike ( ~ 7 - 8 volts above nominal) across the battery terminals. This may be due to a poor design on my part (lack of shielding, no common-mode choke, etc?) but another engineer and myself tried tracking the problem down for several days to no avail. I am not entirely convinced that what we were seeing was "real". I think it may have been radiated from the wires from the battery to the regulator, inducing a voltage on the o-scope probe. No idea really... microcontrollers are really my areas of expertise, I am merely dabbling in power switching. Honestly this problem highlights why I may want to use an isolated smps (forward of flyback). Either way we will be moving the high current path much closer to the instrument this way...

Sorry for the long post, hopefully that clears up some design decisions.

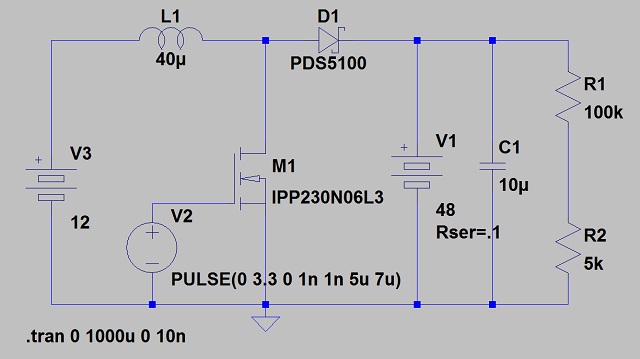

Based on my design criteria does this seem like a reasonable approach? Perhaps there is a charger IC I missed, or maybe a commercial off the shelf charger I do not know about?

Any suggestions, including parts to consider or modifications to my boost converter would be greatly appreciated.

FETs - Single IPP230N06L3G datasheet:http://www.kynix.com/uploadfiles/pdf9675/IPP230N06L3G.pdf

Diodes, Rectifiers - Single PDS5100-13 datasheet:http://www.kynix.com/uploadfiles/pdf65976/PDS5100-13.pdf

Simple boost-style 48V battery charger

Added:

Not sure if this is the correct way to add additional content.

450 W*hr is correct. The internal battery pack is 28 D cell alkaline batteries in series. We wish to use this internal battery back as an "emergency" backup battery. This is useful if we get frayed wires, blown fuses, charger failures or a long streak of cloudy weather. The internal pack and external supply (what I am designing) are diode protected so in any of the above "emergency" cases if our external supply drops below a certain voltage the internal pack will take over and merrily supply the ADCP for another 6-8 months. This is the main reason for selecting 48V for our supply. Yes, we may be capable of modifying the internal pack... but getting permission is another story.

While I fully support the use of LiFePO4 (As an Engineer I think they rock in so many ways), SLA has proven very robust in the harsh marine environment and no one in the group other than myself and possibly one other are interested in trying a new battery technology. Mostly the idea of spending $6k/day to replace a failed battery scares them.

Initially I designed a dual-phase 12V - 48V step up converter (kicad schematic and pcb files) and quickly discovered that this is perhaps infuriating instrument in existence. Shortly before the ADCP collects its ensemble it basically shorts the power pins (it draws > 3A @ 48V for < 10 us). I know it has to boost the voltage to several thousand volts for the transducer so I can only imagine that the ADCP opened a relay to its SMPS. This transient current draw which is is more than 11 A from the main battery causes a large voltage spike ( ~ 7 - 8 volts above nominal) across the battery terminals. This may be due to a poor design on my part (lack of shielding, no common-mode choke, etc?) but another engineer and myself tried tracking the problem down for several days to no avail. I am not entirely convinced that what we were seeing was "real". I think it may have been radiated from the wires from the battery to the regulator, inducing a voltage on the o-scope probe. No idea really... microcontrollers are really my areas of expertise, I am merely dabbling in power switching. Honestly this problem highlights why I may want to use an isolated smps (forward of flyback). Either way we will be moving the high current path much closer to the instrument this way...

Sorry for the long post, hopefully that clears up some design decisions.

Attachments

-

35.5 KB Views: 64